Clean TeQ Pushes Lithium Recovery Boundaries to over 98% with Advanced cDLE® Technology

12 September 2024

The results are in.

Clean TeQ’s cutting-edge cDLE® technology has achieved over 98% lithium recovery from brine in its inaugural pilot campaign in west-central Alberta, surpassing the 90-95% recovery rates of other DLE methods. This significant advancement underscores the strong commercial viability of the cDLE® process.

Clean TeQ’s Continuous Direct Lithium Extraction (cDLE®) technology

>98% Lithium Recovery: cDLE® achieved over 98% lithium recovery in pilot testing.

120-Hour Continuous Operation: Pilot ran for 120 hours, processing 40,000 litres of brine.

Commercial Viability: High lithium recovery rates validate the cDLE® process.

Continuous Direct Lithium Extraction (cDLE®) offers a more efficient, continuous extraction process compared to traditional DLE technologies. Maximizing recovery is essential for profitability, especially with lower concentration Canadian brines, as it translates into increased lithium production and revenue per cubic meter of brine.

The continuous nature of the cDLE technology also reduces downtime, minimising both chemical consumption and freshwater use to support a more sustainable operation.

”“The development of the cDLE® process was all about having a method that recovered all the lithium and minimised the input costs and water use," says Clean TeQ CEO Peter Voigt.

"If we are going to mine these precious and limited resources then let’s do it in the most efficient and sustainable way.”

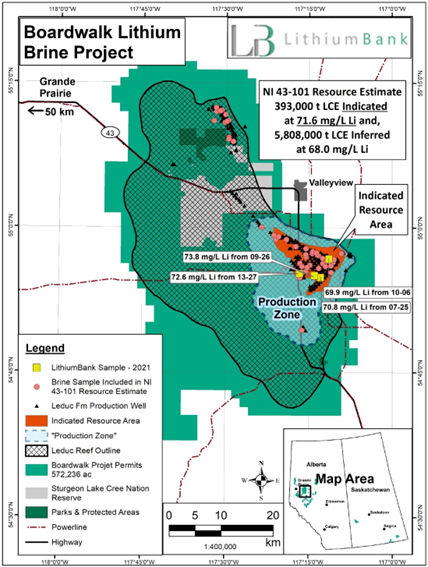

The pilot plant ran continuously for 120 hours, processing 40,000 litres of brine sourced from four wells at LithiumBank’s Boardwalk project. The pilot focused on the recovery of lithium in the absorption section of the cDLE® process. The brine was sampled at each contactor in the circuit and analysed for lithium concentration levels.

LithiumBank’s Boardwalk Brine Project in west central Alberta

The average lithium grade of the feed brine was 70 mg/L (range 67 – 74mg/L), and the barren brine was 0.7 mg/L (range 0.2 – 1.1 mg/L), indicating a recovery of 98 – 99% lithium. These results, consistent with those in LithiumBank’s Preliminary Economic Assessment (“PEA”) in November 2023, demonstrate how cDLE® technology is pushing the boundaries of lithium recovery, setting new standards in the industry.

”“The results from the cDLE® pilot plant are very pleasing,” says Mr Voigt.

“They represent a significant technical milestone for our technology by demonstrating how pivotal it is in lithium extraction, from recovery through to the conservation of water and chemistry.

“One key advantage is our ability to swiftly cost and scale up the process, as it has already been fully engineered for other battery metals. We are excited to continue this collaboration with LithiumBank, complete the Boardwalk project, and proceed with their Park Place asset. As the industry evolves, the cDLE® technology will gain greater recognition for the value it offers to asset owners.”

Canadian brine assets, due to their size and location to US markets and with sustainable extraction technology, will position Canada as a significant player in the future supply of lithium to global markets. LithiumBank’s combined Boardwalk and Park Place projects are one of North America’s largest brine assets, containing over 27Mt of contained lithium carbonate equivalent.

Clean TeQ has granted an exclusive global license for its cDLE® technology to Go2Lithium Inc. (“G2L”), a 50/50 joint venture between Clean TeQ and NYSE-listed Ivanhoe Electric. LithiumBank has entered into an agreement with G2L and its wholly-owned subsidiary, Greenview Resources Ltd., to use the cDLE® technology for its lithium assets in Alberta.