Clean TeQ’s cDLE® Technology Delivers High-Purity Battery-Grade Lithium from Brine

9 December 2024

Clean TeQ’s continuous Direct Lithium Extraction (cDLE®) technology continues to set new benchmarks in lithium recovery. Recent pilot testing in Calgary, Alberta, has delivered outstanding results, strengthening the commercial viability of cDLE® for sustainable lithium production.

Clean TeQ’s cDLE® Pilot Plant in Calgary, Alberta

Pilot Results at a Glance:

>99% impurity removal

>3,000 mg/L lithium in eluate

Battery-grade lithium carbonate produced

In September, we announced the cDLE® process achieved over 98% lithium recovery from brine. Building on that success, further analysis by LithiumBank has shown our technology can remove >99% of impurities, yielding >3,000mg/L lithium in eluate to produce battery-grade lithium carbonate from LithiumBank’s Boardwalk brine in Calgary, Alberta.

The Pilot Process

The pilot, conducted over 120 hours with a 95% uptime, processed 29,000 litres of brine sourced from LithiumBank’s Boardwalk project*. The brine underwent two key stages in our cDLE® plant:

- Adsorption: The brine was first processed through the cDLE® adsorption circuit, where over 98% of the lithium was captured from the solution. This step effectively removed the lithium from the brine while leaving behind other impurities.

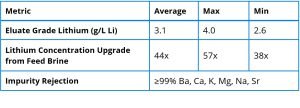

- Desorption: Next, the loaded ion exchange sorbent was treated with a dilute sulfuric acid solution to release the lithium. This process generated multiple lithium-rich liquors (eluates) with concentrations ranging from 2,600 mg/L to over 4,000 mg/L. These were combined to produce a composite eluate averaging over 3,100 mg/L lithium.

Table 1. Eluate quality from the cDLE® pilot

Refining Lithium to Battery-Grade Standards

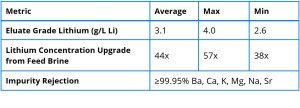

The composite eluate was further processed in a downstream purification and refining step. Using low-cost, industrial-grade reagents, the eluate underwent preliminary purification to reduce impurities while maintaining a high lithium concentration.

Table 2. Eluate quality after preliminary purification

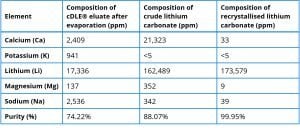

A 5L sample of the eluate was then processed into battery-grade lithium carbonate by Telescope Innovations Corp. Their ReCRFT™ recrystallization process concentrated the eluate, carbonated it to form crude lithium carbonate, and refined it into a final product with a purity exceeding 99.95%.

Table 3. Composition of lithium concentrate, crude and processed lithium carbonate

A Promising Future for Sustainable Lithium

These pilot results reaffirm the potential of Clean TeQ’s cDLE® technology to drive growth in the lithium extraction industry. By delivering high recovery rates, exceptional impurity removal, and battery-grade lithium carbonate, our technology offers a sustainable, efficient solution for meeting the world’s growing demand for lithium.

We’re excited to continue collaborating with partners like LithiumBank to advance the boundaries of lithium recovery and contribute to a greener future.

Stay tuned for more updates as we push the limits of what’s possible with cDLE®.

*Brine was sourced from multiple wells in the Boardwalk project area. A total of 29,000L of brine was put through the adsorption portion of the piloting process and not the previously stated 40,000L of brine.